Wood Laser Cutting Projects for Beginners

Estimated Reading Time: 10 minutes

Key Takeaways

- Laser cutting wood offers precise creation of intricate designs, accessible with various machine types like CO2 and Diode lasers.

- Prioritizing workspace safety (ventilation, fire protection) and selecting appropriate design software are fundamental steps for successful projects.

- Beginners should start with simple projects such as coasters, ornaments, or bookmarks to build confidence and skills, utilizing abundant online design resources.

- Mastering advanced techniques like precise power/speed control, kerf compensation, and multi-layer assembly significantly expands creative possibilities.

- Consistent practice, detailed experimentation with material settings, and meticulous finishing are crucial for evolving from basic to sophisticated wood laser cutting creations.

Table of Contents

- Getting Started with Wood Laser Cutting

- Simple Wood Projects for Beginners

- Advanced Techniques and Design Considerations

- Conclusions

- Frequently Asked Questions

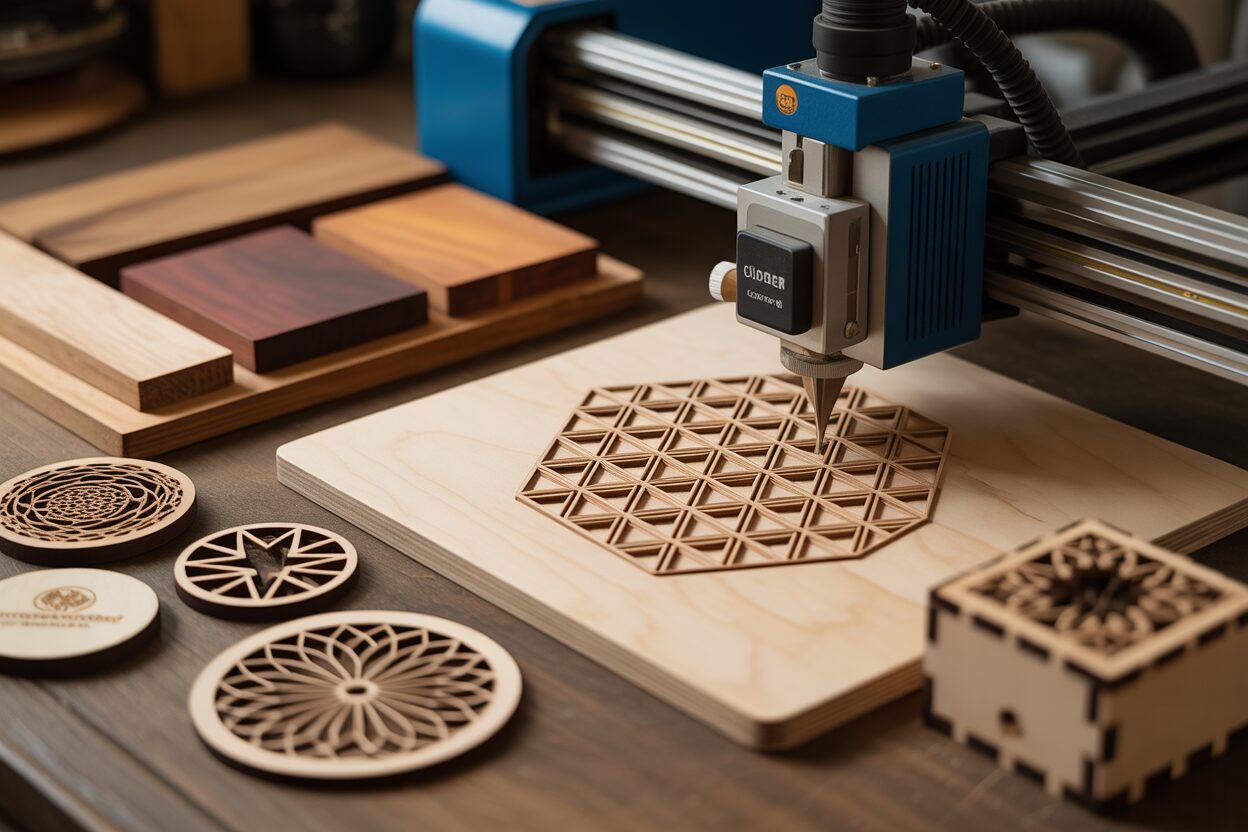

Laser cutting wood opens up endless creative possibilities for crafters and makers of all skill levels. This versatile technology allows precise cutting of intricate designs that would be difficult or impossible with traditional tools. Whether you’re just starting out or looking to expand your project repertoire, understanding the fundamentals of wood laser cutting will help you create beautiful, professional-quality items from the comfort of your workshop.

Getting Started with Wood Laser Cutting

Wood laser cutting harnesses concentrated light energy to precisely cut and engrave wooden materials. Unlike traditional cutting methods, lasers vaporize material along a programmed path, creating clean edges without physical contact. This technology works particularly well with wood because the material absorbs laser energy efficiently, allowing for intricate designs impossible with manual techniques.

Essential Equipment

For beginners exploring laser cutting wood projects, several machine options exist:

- CO2 Lasers ($2,000-$5,000): Most popular for wood, offering excellent cutting power and versatility. Entry-level models like the Glowforge Basic or K40 provide good starting points.

- Diode Lasers ($400-$1,500): Budget-friendly options with lower power, suitable for thin woods and engraving. The Ortur Laser Master or xTool D1 represent affordable entry points.

- Fiber Lasers ($5,000+): Primarily for metals but mentioned for completeness; generally not recommended for wood-focused beginners.

Beyond the machine itself, you’ll need a computer, design software, and proper materials like plywood, basswood, or MDF specifically manufactured for laser cutting.

Workspace Considerations

Creating a safe, functional workspace is crucial when setting up for laser cutting wood projects:

- Ventilation: Proper exhaust systems are non-negotiable. Wood cutting produces smoke and potentially harmful fumes that must be vented outside or through filtration systems.

- Fire Safety: Keep a fire extinguisher rated for electrical fires nearby. Never leave a running laser unattended, and install smoke detectors in your workspace.

- Work Surface: Place your laser cutter on a stable, level surface away from flammable materials. Allow adequate clearance around the machine for airflow and maintenance access.

- Power Requirements: Most entry-level machines run on standard household current, but verify your specific model’s needs.

Software Solutions

The digital design process begins with software that creates or prepares files for your laser cutter:

- Free Options: Inkscape provides powerful vector capabilities without cost. Other free alternatives include LibreCAD and QCAD for technical designs.

- Paid Software: Adobe Illustrator offers professional-grade design capabilities, while CorelDRAW provides dedicated laser features. Expect to invest $20-50/month for these solutions.

- Laser-Specific Software: Most machines include proprietary software like LightBurn ($60 one-time purchase), RDWorks, or manufacturer-specific programs that translate designs into machine instructions.

Basic Workflow

The typical process flows through four stages:

- Design Creation: Develop or source your design in vector format for cutting or raster format for engraving.

- File Preparation: Configure cutting parameters including power, speed, and number of passes based on your wood type and thickness.

- Material Setup: Position your wood properly on the laser bed, ensuring it’s flat and properly focused.

- Execution and Finishing: Run the job, then clean, sand, or finish the completed pieces as needed.

Expect a learning curve as you master material settings, design principles, and machine operation. Most beginners require 5-10 projects before feeling comfortable with the entire process.

Common Challenges and Solutions

New users typically encounter several hurdles when starting laser cutting wood projects:

- Inconsistent Cutting: Solve by ensuring proper focus height and adjusting power/speed settings through test cuts.

- Scorching: Reduce by masking wood with transfer tape or adjusting speed settings.

- Warped Materials: Use hold-down pins or honeycomb beds to keep materials flat.

- Software Complexity: Start with simple designs and gradually build skills through online tutorials specific to your software.

With proper equipment, workspace setup, and a willingness to learn through trial and error, you’ll quickly progress from basic laser cutting wood projects to more complex and rewarding designs.

Simple Wood Projects for Beginners

Now that you understand the fundamentals of laser cutting and have selected appropriate wood materials, it’s time to explore beginner-friendly projects that will help build your confidence and skills. Beginner wood laser cutting projects should balance simplicity with satisfaction, allowing you to experience success while gradually developing more advanced techniques.

Starter Projects with Immediate Rewards

These entry-level projects require minimal design complexity while teaching essential skills:

- Geometric Coasters: Create 3.5-4″ squares or circles from 1/8″ baltic birch plywood with simple engraved patterns. These cut quickly (2-3 minutes each) and teach basic vector design principles while producing functional items.

- Decorative Ornaments: Simple silhouette designs on 1/8″ cherry or maple provide excellent contrast between cut edges and face. Most designs complete in under 5 minutes, making them perfect first projects with minimal material waste.

- Bookmarks: Long, narrow designs (approximately 2″ × 6″) from 1/16″ veneer or thin plywood teach precision cutting and delicate handling. These typically require just 1-2 minutes of cutting time and demonstrate how fine details respond on different woods.

- Name Tags/Signs: Personalized text on 1/8″ wood creates immediately useful items while teaching font selection and text manipulation. These projects typically cut and engrave in 5-7 minutes.

Finding Ready-to-Cut Designs

Before developing your own design skills, take advantage of these resources for beginner wood laser cutting templates:

- Free Repositories: Websites like Thingiverse, Instructables, and Free Laser Designs offer thousands of free, ready-to-cut files specifically optimized for beginners.

- Low-Cost Marketplaces: Etsy and Creative Fabrica sell professional designs ($2-5 each) with detailed instructions and multiple size options.

- Manufacturer Resources: Most laser cutter manufacturers provide starter project libraries with their machines, often with material-specific settings included.

When downloading designs, look specifically for .svg, .dxf, or .ai file formats compatible with your software. For beginners, choosing designs labeled “single pass” or “single layer” ensures straightforward execution.

Progressing to Multi-Component Projects

Once you’ve mastered single-piece designs, these projects introduce assembly concepts:

- Simple Puzzle Designs: 6-12 piece puzzles from 1/8″ maple or cherry teach precise cutting calibration and introduce interlocking components. These typically require 10-15 minutes of cutting time plus assembly.

- Small Boxes: Basic boxes with finger joints or slot construction using 1/8″ plywood introduce structural concepts and assembly techniques. These projects typically require 15-20 minutes of cutting time and teach living hinge principles when incorporating flexible lids.

- Desk Organizers: Simple pen holders or card stands using 1/4″ wood introduce tab-and-slot construction techniques. These functional items generally cut in 10-15 minutes and provide practical experience with 3D assembly from flat components.

Finishing Techniques for Beginners

Enhance your wood laser cutting designs with these beginner-friendly finishing methods:

- Mineral Oil: Simply wipe on this food-safe finish to enhance grain patterns without color changes—ideal for natural wood coasters and kitchen items.

- Water-Based Polyurethane: Apply with a foam brush for durable protection on handled items like bookmarks or puzzle pieces.

- Acrylic Paint: Use in engraved areas for color contrast, wiping excess from the surface to create highlighted details.

- Wood Stains: Apply pre-cutting for uniform color or post-cutting for enhanced edge definition—experiment with both approaches on scrap material first.

Common Beginner Mistakes and Solutions

Avoid these frequent pitfalls in your early projects:

- Improper Material Placement: Always ensure wood is perfectly flat against the cutting bed. Use weights or honeycomb pins for warped materials.

- Incorrect Scale: Double-check measurements before cutting. Many beginners cut designs at incorrect sizes due to software scaling issues.

- Inadequate Edge Cleaning: Keep a soft brush nearby to remove char residue from cut edges before applying finishes.

- Rushing Assembly: When working with multi-component projects, test-fit all pieces before applying glue or finishing materials.

By starting with these simple projects and gradually increasing complexity, you’ll build a foundation of skills that prepares you for the advanced techniques covered in later chapters. Each successful project not only provides satisfaction but also teaches specific aspects of the wood laser cutting process that contribute to your growing expertise.

Advanced Techniques and Design Considerations

As you gain confidence with basic projects, exploring advanced laser cutting techniques for wood opens possibilities for creating truly distinctive pieces. Moving beyond simple cuts and engravings requires understanding how to manipulate your laser’s capabilities and how to design specifically for wood’s unique properties.

Mastering Power and Speed Relationships

The interplay between laser power and cutting speed creates dramatically different results:

- Deep Engraving: Use high power (70-80%) with slow speed (10-15%) to create depth variations up to 3mm in solid hardwoods. This technique works particularly well for relief maps, textured signs, and dimensional artwork.

- Variable Depth Engraving: Utilize grayscale images with power mapping to create subtle depth variations, where darker areas engrave deeper than lighter areas. This technique creates photorealistic portraits or landscapes with extraordinary dimensionality.

- Light Scoring: Apply minimal power (15-20%) at high speeds (80-90%) to create fold lines for bent wood projects or to mark assembly guides without cutting through material.

- Edge Darkening Control: For decorative edges without excessive charring, use multiple passes at medium power rather than a single high-power pass, allowing material to cool between passes.

Document your optimal settings for each material and technique in a personal reference guide, as these will often differ slightly from general recommendations due to your specific machine’s characteristics.

Precision Cutting Refinements

Achieving professional-quality results requires attention to these technical details:

- Kerf Compensation: Account for the 0.15-0.3mm material width removed during cutting by offsetting your design lines by half the kerf width. Most advanced software offers automatic kerf compensation settings.

- Cornering Techniques: Prevent burning at corners by adding 0.5mm overcuts where lines meet or programming a momentary power reduction when the laser changes direction.

- Cutting Sequence Optimization: Arrange cutting paths to minimize head movement and thermal buildup. Cut interior features before exterior outlines to maintain material stability.

- Focus Depth Adjustments: Experiment with slightly defocusing the laser (+/- 1mm from perfect focus) to achieve wider, cleaner cuts with less charring on certain woods.

Multi-Layer and 3D Assembly Strategies

Creating dimensional projects requires careful design consideration:

- Registration Systems: Design alignment pins and corresponding holes (typically 3-4mm diameter) in identical positions across all layers. Include these features outside the final project boundaries for removal after assembly.

- Interlocking Joinery: Design tab-and-slot connections with a 0.1mm tolerance for press-fit assembly. For 1/8″ wood, create 3.3mm slots for 3.2mm material thickness to account for slight charring.

- Living Hinges: Create flexible wood sections by cutting parallel lines (typically 0.5-1mm apart) with uncut sections between them. The spacing and pattern determine flexibility direction and degree of bend.

- Grain Orientation Planning: Design curved components to run with the wood grain, placing stress-bearing joints perpendicular to grain direction to prevent splitting.

Advanced Material Integration

Combining materials elevates wooden projects to new levels:

- Inlay Techniques: Create precise pockets 0.1mm deeper than your inlay material thickness. Cut inlay pieces 0.1mm larger than pockets for perfect press-fits that can be sanded flush.

- Acrylic Integration: Combine wood with laser-cut acrylic for contrasting elements, particularly effective for illuminated projects where acrylic transmits light while wood creates shadows.

- Mixed Media Incorporation: Design specific recesses for non-laser-cut elements like metal hardware, leather components, or electronic modules to create functional, integrated pieces.

Digital Design Optimization

Creating laser-optimized designs requires specific approaches:

- Image Vectorization: Convert photographs to laser-friendly designs using posterization and edge-detection in graphics software before tracing in vector programs. Adjust threshold settings to control detail levels.

- Parametric Design: Utilize software with parametric capabilities (like Fusion 360 or specific laser plugins) to create adjustable designs that automatically recalculate joinery dimensions when scale changes.

- Test Pattern Creation: Develop standardized test patterns with varied settings to quickly calibrate for new wood types. Include fine details, solid areas, and text at different sizes to evaluate results comprehensively.

These advanced laser cutting techniques for wood require practice and experimentation, but they dramatically expand your creative possibilities. Each project becomes an opportunity to refine these methods, combining technical precision with artistic vision to create increasingly sophisticated wooden artifacts.

Conclusions

Wood laser cutting offers beginners an accessible entry point into the world of digital fabrication. By starting with simple projects and gradually building your skills, you’ll soon be creating complex, personalized designs that showcase your creativity. Remember to select appropriate wood types, maintain your machine properly, and always prioritize safety. With practice and experimentation, your laser cutting projects will continue to evolve in complexity and beauty, opening doors to potential business opportunities or simply enhancing your personal making journey.

Frequently Asked Questions

Q: What type of laser cutter is best for beginners working with wood?

A: For wood, CO2 lasers ($2,000-$5,000) are most popular, offering excellent cutting power and versatility, with entry-level models like Glowforge Basic or K40. Diode lasers ($400-$1,500) are budget-friendly alternatives suitable for thin woods and engraving.

Q: What are the essential safety considerations for laser cutting wood?

A: Crucial safety measures include proper ventilation to exhaust fumes, keeping a fire extinguisher nearby (rated for electrical fires), never leaving the machine unattended, and placing it on a stable surface away from flammable materials. Install smoke detectors in your workspace.

Q: What kind of software do I need for wood laser cutting?

A: You’ll need design software (e.g., free options like Inkscape, or paid like Adobe Illustrator/CorelDRAW) to create or prepare files. Most machines also come with proprietary laser-specific software (e.g., LightBurn, RDWorks) to translate designs into machine instructions.

Q: What are some easy first projects for wood laser cutting beginners?

A: Excellent starter projects include geometric coasters, decorative ornaments, bookmarks, and name tags/signs. These projects require minimal design complexity, cut quickly, and teach essential skills while producing functional items.

Interested in more Ornaments? Check out our Ornaments laser file designs: Click here!

Q: How can I prevent common issues like scorching or inconsistent cuts?

A: For inconsistent cutting, ensure proper focus height and adjust power/speed settings. To reduce scorching, mask the wood with transfer tape or fine-tune speed settings. For warped materials, use hold-down pins or a honeycomb bed to keep them flat during cutting.

Subscribe to Our Newsletter

And enjoy FREE Download Files, SALE Alerts and Inspiring TIPS

A Beginner’s Guide to Creating 3D Illusion Laser Engravings

A Beginner’s Guide to Crafting the Perfect Laser Cut Box

Creative Laser Cut Box Projects for Every Occasion

Charcuterie Board Engraving File – Wine & Grapes 3D Illusion…

$4.00Original price was: $4.00.$3.00Current price is: $3.00.(25% off)

Bee and Honey Jar Charcuterie Board Engraving File | PNG Download #007…

$4.00Original price was: $4.00.$3.20Current price is: $3.20.(20% off)

Valentine Love Captions: 6 Charcuterie Board Engraving Files…

$8.00Original price was: $8.00.$5.60Current price is: $5.60.(30% off)

American Eagle Flag Laser Engraving File for Charcuterie & Cutting…

$4.00Original price was: $4.00.$2.80Current price is: $2.80.(30% off)