Laser Stippling: Revolutionizing Texture Creation in Manufacturing

Estimated Reading Time: 19 minutes

Key Takeaways

- Laser stippling offers superior precision, repeatability, and efficiency compared to traditional methods, yielding consistent, high-quality textures.

- This non-contact process utilizes focused laser energy for versatile material removal across various substrates, including metals, polymers, and ceramics.

- It is widely adopted in industries such as firearms, automotive, medical devices, and consumer electronics to enhance grip, aesthetics, and overall product functionality.

- Advanced software, digital design, and AI integration are revolutionizing pattern creation, allowing for complex, customized, and functionally optimized textures, including tactile branding.

- Setting up a laser stippling workflow involves careful selection of equipment (laser source, cooling, motion systems), comprehensive software, stringent safety measures, and a structured process for design, parameter development, and post-processing.

Table of Contents

- Understanding Laser Stippling Technology

- Benefits Over Traditional Stippling Methods

- Industrial Applications and Case Studies

- Setting Up Your Own Laser Stippling Workflow

- Creative Design Possibilities and Future Trends

- Conclusions

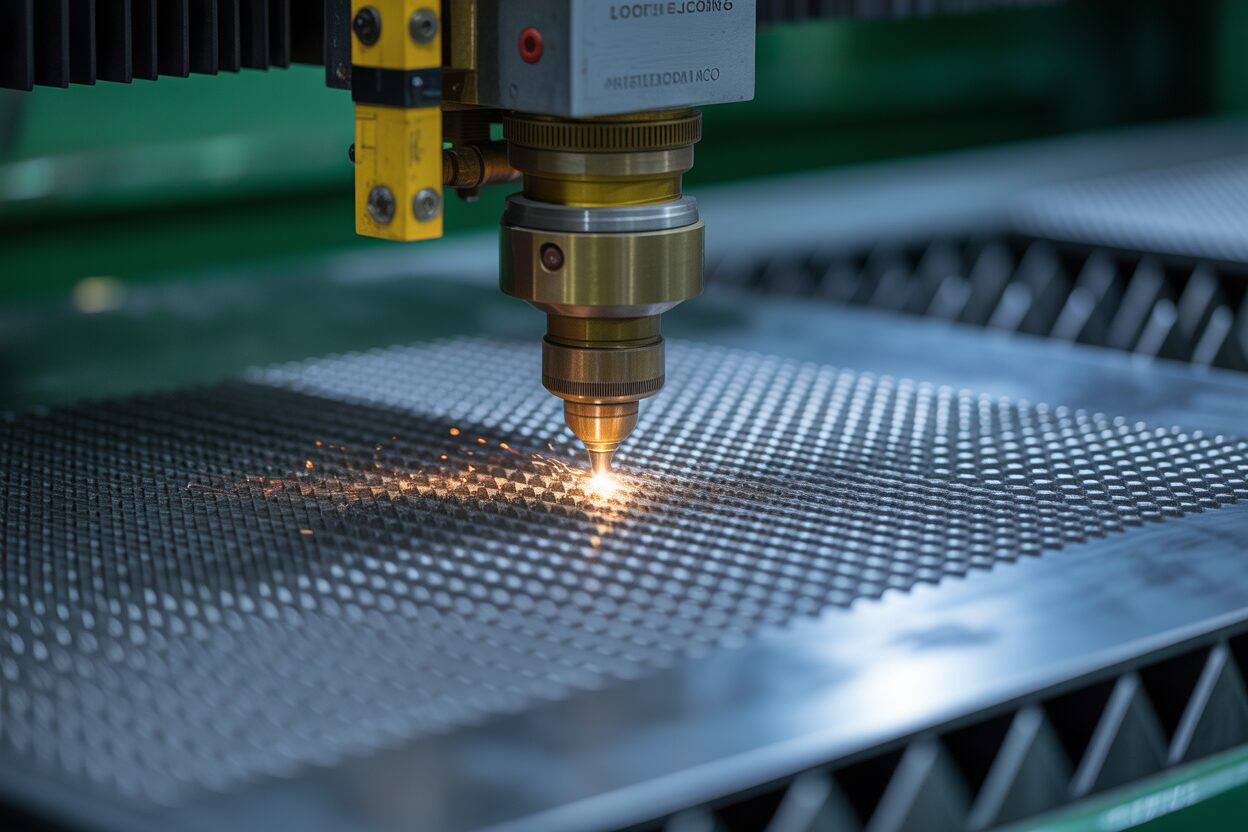

Laser stippling represents a significant advancement in texture creation technology, offering unprecedented precision and consistency compared to traditional manual methods. This innovative technique uses focused laser energy to create microscopic depressions in material surfaces, producing customized textures that enhance grip, aesthetics, and functionality. As industries increasingly demand higher quality finishes with reduced production time, laser stippling has emerged as the definitive solution for modern manufacturing challenges.

Understanding Laser Stippling Technology

Laser stippling represents a significant evolution in surface texturing technology, offering unprecedented precision in creating textured surfaces through controlled material removal. At its core, laser stippling is a process that utilizes focused laser energy to selectively ablate material at a microscopic level, creating patterns of tiny depressions or dots that collectively form a textured surface.

The Fundamental Process

Unlike traditional stippling methods which rely on physical impact to create texture, laser stippling functions through a non-contact thermal process. When the laser beam strikes the workpiece surface, it rapidly heats the target area to its vaporization temperature, causing a minute amount of material to be ejected from the surface. This process, known as laser ablation, occurs in an incredibly localized manner—often affecting areas measuring just microns in diameter. The laser beam moves across the surface according to pre-programmed patterns, creating thousands of individual stipple points that collectively form the desired texture.

The depth and character of each stipple point are precisely controlled by manipulating key parameters including laser power, pulse duration, frequency, and focal distance. This level of control enables the creation of textures with consistent depths ranging from a few microns to several hundred microns, depending on the application requirements.

Comparison with Traditional Methods

Traditional stippling techniques involve either manual processes using hammers and punches or semi-automated methods utilizing pneumatic stippling guns. These conventional approaches rely on physical impact to displace material, creating indentations that form the stippled pattern. While effective for certain applications, these methods suffer from several limitations that laser stippling overcomes.

Manual stippling depends heavily on operator skill, making consistency difficult to achieve across large areas or multiple parts. Pneumatic stippling tools offer some improvement in consistency but still cannot match the precision of laser processes. Additionally, traditional metal stippling techniques often result in material displacement rather than removal, creating raised edges around each stipple point that may require secondary processing to address.

Physics and Laser Types

The effectiveness of laser stippling varies significantly based on the type of laser employed and its interaction with different materials. CO2 lasers, operating at a wavelength of 10.6 micrometers, excel at processing organic materials and certain polymers but are less effective on metals. Conversely, fiber lasers with wavelengths around 1064 nanometers are highly absorbed by metals, making them ideal for metal stippling techniques.

Nanosecond pulsed lasers are commonly used for stippling applications, as they deliver high peak power in extremely short bursts, allowing for precise material removal with minimal heat-affected zones. For applications requiring even greater precision, picosecond and femtosecond lasers offer “cold ablation,” where material is removed with negligible heat transfer to surrounding areas.

Equipment and System Requirements

A complete laser stippling system comprises several key components beyond just the laser source. Modern laser stippling equipment typically includes:

- Laser source (CO2, fiber, or solid-state depending on application)

- Beam delivery system with precision optics

- Computer-controlled galvanometer scanners for beam positioning

- Precision motion control systems for workpiece positioning

- Sophisticated control software for pattern generation and process management

- Filtration systems for capturing ablated material

Power requirements vary significantly based on application, with systems ranging from 20W for fine detail work on soft materials to 500W or more for high-throughput industrial applications on metals and composites.

Technological Advancements

Recent years have seen remarkable advancements in laser stippling technology, making these systems more accessible and capable. Improvements in beam quality and control have enabled finer resolution patterns, while increases in processing speed have made laser stippling economically viable for mass production environments. The integration of advanced sensors for real-time process monitoring has further enhanced quality control capabilities, ensuring consistent results across production runs.

Perhaps most significantly, advancements in computer-aided design have revolutionized pattern generation for laser stippling. Modern software allows designers to create complex, non-repeating patterns with varying densities and depths—something impossible with traditional stippling methods. These digital designs are directly translated to machine instructions, ensuring perfect replication of the intended texture without human variability.

As laser technology continues to advance, laser stippling is becoming increasingly accessible to smaller manufacturers, opening new possibilities for creative surface texturing across numerous industries.

Benefits Over Traditional Stippling Methods

Superior Precision: The Defining Advantage

Laser stippling stands as one of the most effective stippling gun alternatives available in modern manufacturing, delivering unprecedented levels of precision impossible to achieve through conventional methods. While traditional stippling techniques rely on manual dexterity or pneumatic tool control, laser systems can achieve microscopic accuracy with depth variations as precise as 0.001mm. This exceptional control enables manufacturers to create textures with exact pattern density specifications that remain consistent across the entire workpiece. The ability to precisely control the depth of material removal results in textures that provide optimal friction characteristics for applications such as textured firearm grips, where consistent hand feel directly impacts user performance and safety.

Unmatched Repeatability and Consistency

Perhaps the most significant advantage laser stippling offers over traditional methods is perfect repeatability. Once a pattern is programmed and optimized, the laser system can reproduce identical results across hundreds or thousands of parts without deviation. This level of consistency eliminates the quality variations inherent in manual stippling processes, where even skilled technicians produce slight differences between workpieces. For manufacturers producing components in high volumes, this repeatability translates directly to improved quality metrics and reduced rejection rates. The computer-controlled nature of laser stippling ensures that the thousandth part receives exactly the same treatment as the first, maintaining dimensional tolerances and surface characteristics throughout production runs.

Efficiency and Production Speed

The speed advantages of laser stippling become particularly evident when creating complex patterns or working with challenging materials. While a skilled craftsman using traditional metal stippling techniques might require hours to complete intricate texturing on a single component, modern laser systems can complete the same work in minutes. This efficiency scales dramatically with batch size—as production volumes increase, the time savings compound. For manufacturers, this translates to significantly reduced labor costs and improved production throughput. Additionally, laser systems can operate continuously without the fatigue factors that affect manual operations, maintaining consistent quality over extended production runs.

Material Versatility Without Compromises

Laser stippling equipment demonstrates remarkable versatility across material types, efficiently processing metals, polymers, composites, and ceramics without requiring tool changes or significant parameter adjustments. This versatility eliminates the need for specialized tooling for different materials, reducing inventory costs and setup times. Traditional stippling methods often struggle with harder materials, requiring different tool types and increased physical force that can lead to operator fatigue and inconsistent results. The adaptability of laser systems also extends to accommodating different surface geometries, including curved or complex shapes that prove challenging for conventional stippling techniques.

The Non-Contact Advantage

One of the most overlooked benefits of laser stippling is its non-contact nature. Unlike traditional methods that rely on physical impact or abrasion, laser energy never physically touches the workpiece beyond the photonic interaction. This eliminates tool wear issues entirely—there are no bits to replace, no hammer heads to maintain, and no pneumatic tips to inspect. The absence of physical contact also prevents unwanted material deformation that can occur with traditional stippling gun alternatives. For precision industries like medical device manufacturing or aerospace components, this non-contact advantage preserves the dimensional integrity of parts while adding functional textures.

Reduced Waste and Environmental Impact

Laser stippling generates significantly less waste material compared to traditional methods. The precision of the process removes only the exact amount of material required to create the desired texture, unlike manual techniques that often remove excess material through imprecise application. This efficiency reduces cleanup requirements and material waste, contributing to more sustainable manufacturing practices. Additionally, many laser stippling systems incorporate vacuum extraction that captures removed material particles, preventing workplace contamination and facilitating proper disposal or recycling of materials.

Customization and Design Freedom

Computer-controlled patterns enable customization options impossible with manual techniques. Manufacturers can create gradient patterns, incorporate logos or functional elements, and even personalize products with serial numbers or customer-specific identifiers within the same stippling process. This design freedom allows for textures that not only serve functional requirements but also enhance aesthetic appeal and brand identity. For industrial stippling applications requiring both functionality and visual appeal, laser stippling provides unmatched capabilities to satisfy complex design briefs without sacrificing production efficiency.

Balancing Considerations

While the advantages of laser stippling are substantial, honest assessment requires acknowledging certain limitations. The initial equipment investment exceeds that of traditional stippling tools, creating a higher barrier to entry for smaller operations. However, rapid return on investment through labor savings, reduced material waste, and higher quality production typically offsets these initial costs within months for operations with moderate to high production volumes. The technology also requires technical expertise for programming and maintenance, though modern systems have become increasingly user-friendly with intuitive interfaces and pre-programmed pattern libraries that reduce the learning curve significantly.

Industrial Applications and Case Studies

Laser stippling technology has rapidly transformed manufacturing processes across diverse sectors, offering unprecedented texture creation capabilities that meet stringent industrial requirements. This revolutionary approach to surface modification has found applications far beyond its initial adoption, demonstrating remarkable versatility and effectiveness.

Firearms Industry: Precision Grip Enhancement

The firearms industry represents one of the most prominent adopters of laser stippling technology. Leading manufacturers like Glock and Smith & Wesson have implemented laser systems to create textured firearm grips that significantly outperform traditional hand-stippled surfaces. These precisely engineered patterns enhance control during discharge while maintaining shooter comfort through extended use.

SIG Sauer’s implementation of laser stippling in their P320 series demonstrates the technology’s value proposition. Their proprietary pattern creates a tactile surface that maintains grip integrity even in adverse weather conditions or when the operator’s hands are perspiring. The computer-controlled laser stippling equipment allows for consistent pattern application across thousands of units, ensuring quality uniformity impossible with manual methods.

Agency Arms, a premium firearm customization company, utilizes advanced laser stippling for their modified Glock frames, applying proprietary patterns that combine both functional grip enhancement and aesthetic appeal. Their documented reduction in production time—from hours per frame with manual methods to under 15 minutes with laser technology—exemplifies the efficiency gains possible.

Automotive Applications: Enhancing User Experience

The automotive industry has embraced laser stippling for both functional and decorative applications. BMW incorporates laser-stippled surfaces on control interfaces and grip points throughout their vehicle interiors. These subtle texture variations create intuitive tactile feedback for drivers, allowing for interaction without visual confirmation.

Tesla employs metal stippling techniques on steering wheel components and control surfaces, creating durable textures that resist wear while enhancing the premium feel of their vehicles. Their implementation demonstrates how laser stippling can be tailored to specific material properties—in this case, aluminum components requiring both aesthetic appeal and functional grip.

Faurecia, a major automotive supplier, documented a 32% improvement in production efficiency after transitioning from mechanical texturing methods to laser stippling for interior components. Their case study highlights both cost savings and quality improvements across high-volume production runs.

Medical Device Applications: Safety Through Superior Grip

The medical sector has adopted laser stippling for critical applications where reliable grip characteristics directly impact patient outcomes. Stryker Corporation implements precise laser stippling patterns on surgical instruments, creating textured surfaces that maintain secure handling even in fluid-rich environments. Their specialized patterns, developed through extensive testing, demonstrate how laser stippling can be optimized for specific operational contexts.

Medtronic utilizes laser stippling equipment modified for medical-grade materials, creating textures on instrument handles that enhance surgeon control during delicate procedures. Their implementation includes specialized clean-room compatible systems that maintain sterile manufacturing environments while delivering precision texturing.

Boston Scientific’s application of laser stippling to endoscopic tools represents an innovative use case where microscopic texture patterns improve instrument manipulation in minimally invasive procedures. Their documented 28% reduction in surgical grip failures after implementing laser-stippled handles demonstrates the technology’s direct impact on medical outcomes.

Consumer Electronics: Ergonomics and Brand Differentiation

Consumer electronics manufacturers leverage laser stippling for both functional and brand identity purposes. Apple employs subtle laser-stippled textures on select products to enhance ergonomics while maintaining their minimalist design language. Their precision application demonstrates how even minimal texturing can significantly improve user experience.

Microsoft’s Xbox controller division implemented laser stippling as an alternative to traditional rubberized coatings, creating durable grip surfaces that resist degradation over time. Their transition from chemical coating processes to direct laser stippling represents both a quality improvement and an environmental benefit by eliminating volatile compounds from their manufacturing process.

Logitech documented a 40% increase in product lifespan for their high-performance gaming peripherals after implementing laser-stippled grip zones, demonstrating the technology’s contribution to product durability and customer satisfaction.

Emerging Applications

Aerospace manufacturers are increasingly adopting industrial stippling applications for cockpit controls and maintenance access points, creating tactile identification systems that function in low-visibility conditions. Sports equipment manufacturers implement laser stippling for golf club grips, tennis racket handles, and other contact surfaces requiring controlled friction characteristics. The technology continues to expand into new sectors as manufacturers recognize its unique capabilities for combining functional texturing with aesthetic design elements.

As these diverse case studies demonstrate, laser stippling has established itself as an essential manufacturing technology across industries where precision texture creation directly impacts product performance, user experience, and production efficiency.

Setting Up Your Own Laser Stippling Workflow

Assessing Your Requirements

Before investing in laser stippling equipment, carefully evaluate your intended applications. Different projects demand specific configurations—small-scale custom firearm grip texturing requires different capabilities than high-volume automotive component production. Consider your production volume, material types, and desired texture complexity to determine the appropriate scale of your setup.

Essential Equipment Components

Laser Source Selection

The heart of your stippling system is the laser source. Fiber lasers excel at metal stippling techniques, providing exceptional precision for detailed patterns on firearms and medical instruments. CO2 lasers work well for organic materials and some plastics, while YAG lasers offer versatility across multiple substrates. For professional textured firearm grips, fiber lasers in the 20-50W range typically provide ideal results.

Power and Cooling Requirements

Match laser power to your materials—thicker metals require higher power (50W+), while plastics and thin metals can be processed with lower power systems (20-30W). Adequate cooling is critical; recirculating chillers prevent overheating during extended operation and ensure consistent beam quality.

Motion System

Precision galvanometer scanners provide the fastest processing for detailed patterns, while mechanical XY tables offer larger work areas for industrial stippling applications. The motion system’s resolution directly impacts your pattern precision—look for systems offering at least 0.001″ positioning accuracy.

Safety Equipment

Never compromise on safety. Proper enclosures with interlocks, laser-specific eye protection, fume extraction systems, and fire suppression equipment are essential. These components not only protect operators but also ensure compliance with regulatory requirements.

Software Considerations

Design Software

Vector-based CAD programs (Adobe Illustrator, CorelDRAW, or Inkscape) enable pattern creation, while specialized 3D modeling software helps when working with complex contoured surfaces. Some advanced users combine both approaches, designing patterns in 2D and mapping them to 3D surfaces.

Laser Control Software

This interface translates your designs into laser movement instructions. Quality control software should offer parameter libraries for different materials, pattern preview capabilities, and fine control over laser parameters including power, frequency, pulse duration, and scanning speed.

Establishing Your Workflow Process

1. Design Creation

Begin with pattern development in your design software, considering both functional and aesthetic requirements. For textured firearm grips, balance aggressive texture for grip with comfort for extended use.

2. Parameter Development

Each material requires specific laser settings. Develop a testing protocol with small samples to determine optimal parameters before processing valuable parts. Document successful parameters for future reference.

3. Fixturing and Positioning

Create consistent holding systems for your workpieces to ensure accurate pattern placement. For contoured surfaces like firearm grips, custom fixtures maintain proper focus distance across the entire work surface.

4. Processing

Execute your stippling operation with appropriate ventilation active. Monitor the first few pieces carefully before committing to production runs.

5. Post-Processing

Depending on your application, parts may require cleaning, coating, or other finishing operations after stippling.

Workspace Considerations

Designate a dedicated area with adequate electrical service (typically 220V for larger systems), proper ventilation, controlled humidity, and minimal dust. Unlike traditional stippling gun alternatives, laser systems require minimal physical space but demand controlled environmental conditions for optimal performance.

Maintenance Requirements

Implement a regular maintenance schedule including optics cleaning, cooling system service, and mechanical alignment checks. Daily, weekly, and monthly maintenance routines significantly extend equipment life and maintain consistent quality.

Investment Considerations

Entry-level laser stippling systems start around $15,000, while comprehensive industrial solutions can exceed $100,000. For small businesses, lease options can reduce initial capital requirements. ROI typically ranges from 6-18 months depending on production volume and market positioning.

Troubleshooting Common Issues

Be prepared to address common challenges including inconsistent depth, pattern distortion on curved surfaces, and thermal effects on sensitive materials. Systematic problem-solving approaches—adjusting focus distance, modifying scan patterns, or altering power delivery timing—resolve most issues encountered during initial setup.

By methodically establishing your laser stippling workflow with appropriate equipment, software, and processes, you’ll create a production capability that far exceeds traditional manual stippling methods in both quality and efficiency.

Creative Design Possibilities and Future Trends

Digital Pattern Creation: Breaking Traditional Boundaries

Laser stippling has fundamentally transformed what designers can achieve with texture. Unlike traditional stippling methods that rely on manual techniques with limited precision, digital pattern creation enables designers to develop intricate textures with unprecedented control. The technology allows for the creation of complex geometric patterns, organic textures, and functional surfaces that would be impossible to achieve consistently with conventional methods.

The precision of laser stippling technology enables designers to work with microscopic detail, creating patterns that can be felt by hand yet are precisely controlled at the pixel level. This marriage of digital design and physical texture has opened new avenues for creative expression across multiple industries.

Pattern Libraries and Customization

One of the most exciting developments in laser stippling is the emergence of extensive pattern libraries that can be modified and combined to create signature textures. These range from purely functional grip patterns that enhance ergonomics to decorative motifs that serve aesthetic purposes. Industries from automotive interiors to consumer electronics are leveraging these capabilities to differentiate their products through touch.

In the firearms industry, textured firearm grips have evolved from basic stippling to highly customized patterns that combine ergonomic function with distinctive branding elements. Manufacturers are now offering consumers personalized grip textures that match hand anthropometrics while incorporating visual elements that set their products apart in a competitive market.

Depth, Density, and Dimension

The true revolution in laser stippling comes from the ability to vary depth and density within a single pattern. This capability creates surfaces with zones of different tactile feedback – crucial for applications where intuitive grip positioning is important. For example, a tool handle might feature deeper stippling where maximum grip is needed and shallower patterns in areas meant for lighter touch.

These variable patterns create visual dimension as well, with light interacting differently across the textured surface. Metal stippling techniques have particularly benefited from this capability, as different depths create subtle variations in how light reflects off the surface, resulting in a dynamic appearance that changes based on viewing angle.

Signature Textures as Brand Identifiers

Forward-thinking companies are now developing proprietary stippled textures that serve as tactile brand signatures. Just as visual logos identify a brand at a glance, these textured elements create immediate brand recognition through touch. Luxury automotive manufacturers are among the early adopters, using laser stippling to create distinctive interior surfaces that customers associate with their brand experience.

This trend toward “tactile branding” represents one of the most innovative applications of industrial stippling applications, creating a new dimension of customer experience that engages multiple senses.

Hybrid Surface Treatments

The integration of laser stippling with other surface treatments represents another frontier in texture creation. Manufacturers are combining stippling with anodizing, PVD coating, and other finishing processes to create multi-functional surfaces. These hybrid approaches can yield textures with enhanced durability, corrosion resistance, or even antimicrobial properties while maintaining precise tactile characteristics.

For example, medical device manufacturers are exploring stippled surfaces with antimicrobial coatings for equipment handles, creating both improved grip security and enhanced infection control. This convergence of functional stippling with additional surface properties is opening new possibilities for specialized applications.

Future Directions

The future of laser stippling technology points toward greater integration and accessibility. As laser stippling equipment becomes more affordable and compact, smaller manufacturers and even individual designers are gaining access to capabilities once limited to large industrial operations. This democratization of the technology is driving innovation as new users bring fresh perspectives to texture creation.

Integration with Automated Manufacturing

Industry 4.0 principles are transforming how laser stippling integrates with broader manufacturing processes. Robotic systems capable of manipulating components for stippling are being integrated with laser equipment, allowing for automated processing of complex three-dimensional objects. This integration is reducing production time while enabling stippling on geometrically complex surfaces that would be difficult to process manually.

AI and Generative Design

Perhaps the most exciting frontier is the application of artificial intelligence to pattern development. Generative design algorithms are beginning to create stippling patterns optimized for specific performance characteristics – such as maximum grip under wet conditions or optimal heat dissipation – while maintaining aesthetic appeal. These AI-driven approaches are pushing beyond human-designed patterns to discover new texture possibilities that might otherwise remain unexplored.

As computational power increases, real-time simulation of how different stippling patterns will perform under various conditions is becoming possible, allowing designers to virtually test and refine textures before committing them to physical production.

The evolution of laser stippling from a purely functional technology to a creative medium continues to accelerate. As designers push the boundaries of what’s possible and manufacturers adopt increasingly sophisticated laser stippling equipment, we can expect to see texture become an even more important element of product design – engaging our sense of touch in ways that enrich our interaction with the objects around us.

Conclusions

Laser stippling continues to transform how industries approach texture creation, with ongoing innovations making the technology more accessible and versatile than ever before. Whether for improving product functionality through enhanced grip surfaces, creating distinctive aesthetic finishes, or enabling new manufacturing capabilities, laser stippling represents the future of texture application. By embracing this technology and understanding its unique advantages, manufacturers and craftspeople can achieve superior results while simultaneously reducing production time and expanding their creative possibilities.

Frequently Asked Questions

Q: What is laser stippling?

A: Laser stippling is an advanced surface texturing technology that uses focused laser energy to create microscopic depressions or dots on a material’s surface through controlled ablation, enhancing grip, aesthetics, and functionality.

Q: How does laser stippling differ from traditional methods?

A: Unlike traditional methods that rely on physical impact, laser stippling is a non-contact thermal process offering superior precision, perfect repeatability, and higher consistency. It also provides greater material versatility and significantly faster production speeds.

Q: What industries primarily benefit from laser stippling?

A: Key industries benefiting from laser stippling include firearms (for grip enhancement), automotive (for interior controls and aesthetics), medical devices (for secure instrument handling), and consumer electronics (for ergonomics and brand differentiation).

Q: What equipment is needed for a basic laser stippling setup?

A: A basic setup typically includes a laser source (e.g., fiber laser for metals, CO2 for plastics), a beam delivery system with precision optics, computer-controlled galvanometer scanners, sophisticated control software, and essential safety equipment like fume extraction and eye protection.

Q: Can laser stippling be used for custom designs or branding?

A: Yes, laser stippling offers extensive customization and design freedom. Computer-controlled patterns allow for complex designs, variable depths and densities, integration of logos, serial numbers, and even tactile brand signatures, enabling unique functional and aesthetic outcomes.

Subscribe to Our Newsletter

And enjoy FREE Download Files, SALE Alerts and Inspiring TIPS

A Beginner’s Guide to Creating 3D Illusion Laser Engravings

A Beginner’s Guide to Crafting the Perfect Laser Cut Box

Creative Laser Cut Box Projects for Every Occasion

Charcuterie Board Engraving File – Wine & Grapes 3D Illusion…

$4.00Original price was: $4.00.$3.00Current price is: $3.00.(25% off)

Bee and Honey Jar Charcuterie Board Engraving File | PNG Download #007…

$4.00Original price was: $4.00.$3.20Current price is: $3.20.(20% off)

Valentine Love Captions: 6 Charcuterie Board Engraving Files…

$8.00Original price was: $8.00.$5.60Current price is: $5.60.(30% off)

American Eagle Flag Laser Engraving File for Charcuterie & Cutting…

$4.00Original price was: $4.00.$2.80Current price is: $2.80.(30% off)