-

×

Bee and Honey Jar Charcuterie Board Engraving | PNG Download #008 1 ×

Bee and Honey Jar Charcuterie Board Engraving | PNG Download #008 1 ×$4.00Original price was: $4.00.$0.00Current price is: $0.00.Free Download

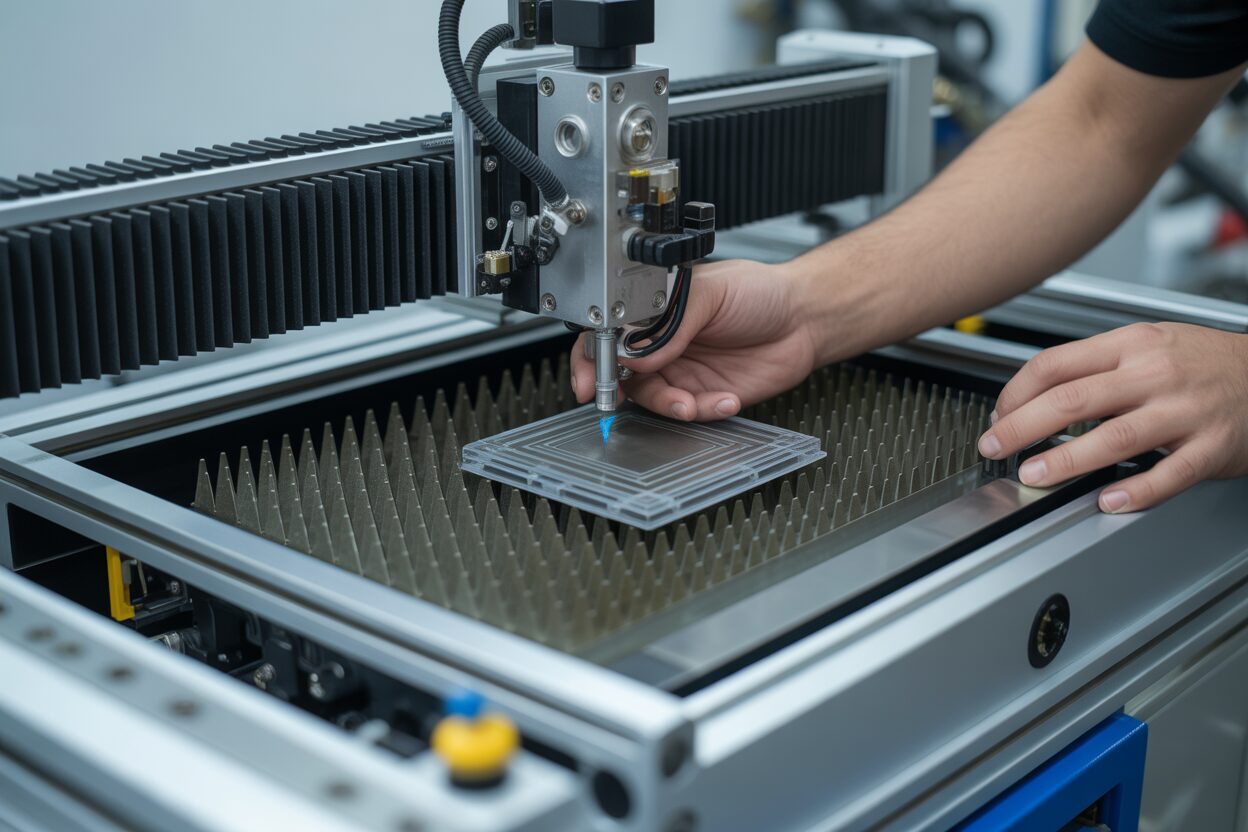

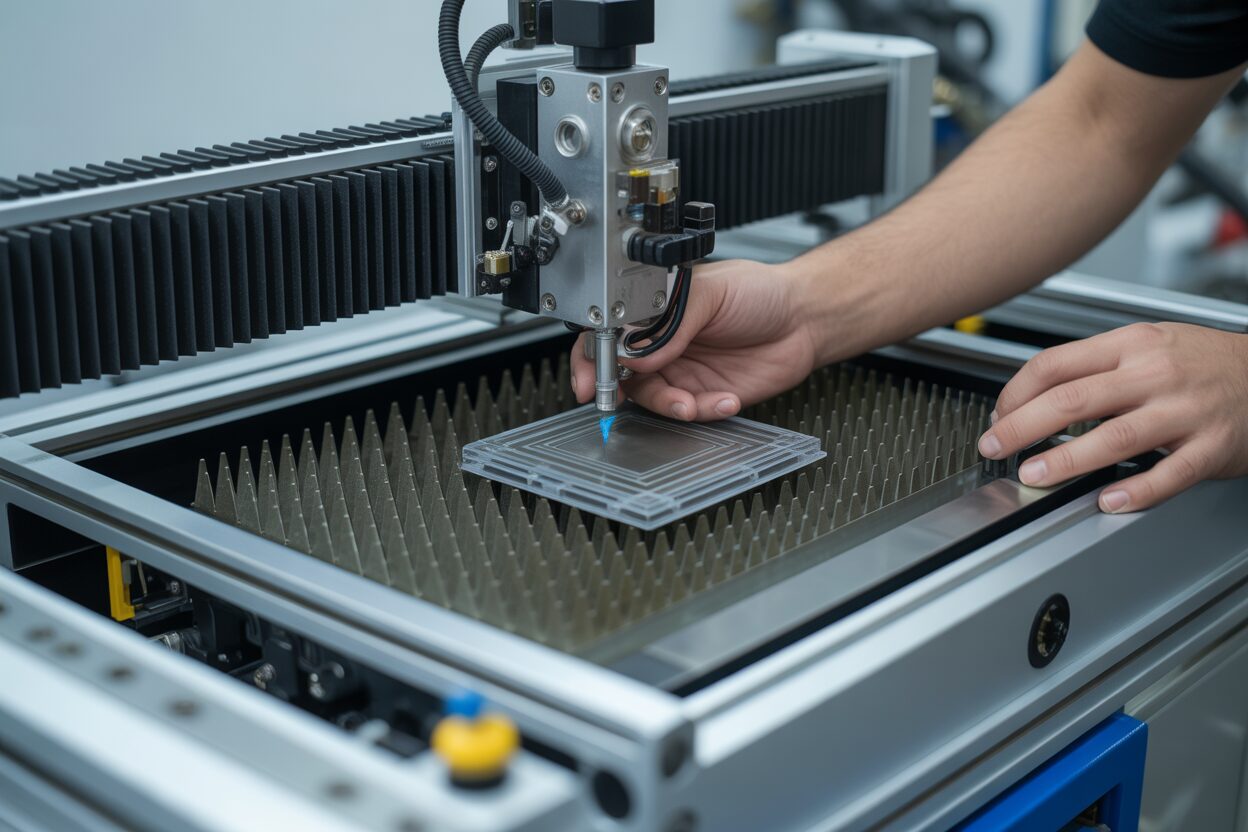

How to Maintain Your Laser Engraving Machine for Optimum Performance

Estimated reading time: 7 minutes

Key Takeaways

- Routine Cleaning is Paramount: Regularly cleaning laser optics, rails, and the work area prevents performance degradation, power loss, and premature component failure.

- Preventative Maintenance Extends Lifespan: Lubricating mechanical parts, inspecting belts, and maintaining air assist and cooling systems are crucial for longevity and consistent performance.

- Software & Organization Matter: Keeping software/firmware updated and maintaining a detailed maintenance log/schedule ensures continued productivity and aids in troubleshooting.

- Avoid Common Mistakes: Using incorrect cleaning materials, neglecting filters, over-lubricating, or ignoring worn consumables can lead to costly damages.

- Systematic Troubleshooting: A structured approach to diagnosing issues, starting with optics and alignment, can quickly resolve performance problems and minimize downtime.

Table of Contents

- Routine Cleaning and Laser Optics Care

- Preventative Maintenance for a Longer Machine Lifespan

- Avoiding Common Maintenance Mistakes and Troubleshooting Performance Issues

- Conclusions

Proper maintenance is crucial for keeping your laser engraving machine running smoothly and efficiently. In this guide, we’ll delve into the best practices and critical steps to ensure your equipment’s longevity, performance, and safety. Learn how routine care can prevent costly repairs and extend the useful life of your engraver.

Routine Cleaning and Laser Optics Care

Neglecting routine cleaning is one of the most common maintenance mistakes that can significantly impact laser engraving machine maintenance. Buildup of dust, smoke, and residue not only diminishes engraver performance but also leads to power loss, reduced accuracy, and even premature component failure. Cleaning laser optics—specifically the lenses and mirrors—prevents energy scattering and ensures laser beams remain focused, which translates directly into sharper, more precise designs. Maintaining cleanliness across the machine’s rails, laser head, and surrounding work area is just as crucial for preventing misalignment and extending machine lifespan.

Laser Optics: Why Cleanliness Matters

Lenses and mirrors are the heart of laser engraving, focusing and directing the laser beam accurately onto your workpiece. When these surfaces are tainted with dust or residue, the laser loses power and can scatter unpredictably, resulting in faded engravings, distorted edges, and design inconsistency. Dirty optics also absorb heat, risking permanent damage and increasing operational costs over time. Regular cleaning is a cornerstone of preventative care for engravers, preventing unnecessary troubleshooting of laser performance issues and ensuring optimal results on every project.

Step-by-Step Guide to Safe Cleaning

- Power Down and Isolate the Machine: Always switch off and unplug your machine before cleaning laser optics to protect sensitive components and yourself.

- Accessing Optics: Carefully remove any protective housings around the lens and mirrors according to the manufacturer’s directions.

- Inspect with Care: Use a magnifying loupe or lamp to check for dust, smudges, or residue build-up. Take note of areas needing attention for more focused cleaning.

- Use Recommended Cleaning Solutions: Employ only lens-safe cleaners, such as isopropyl alcohol or specialized optical solutions, to avoid etching delicate surfaces. Avoid aggressive chemicals that can scratch or degrade optics.

- Choose the Right Tools: Always use lint-free optical wipes, soft microfiber cloths, or cotton swabs. Do not use standard paper towels or clothing which can shed fibers or cause scratches.

- Gentle Cleaning Technique: Lightly dampen a wipe or swab with cleaning solution. Using minimal pressure, gently wipe the lens or mirror in a single direction to lift residue away from the surface. Do not scrub or use a circular motion, as this can cause micro-abrasions.

- Drying and Reassembly: Allow optical components to fully air dry before replacing covers. Check for any remaining streaks or spots and repeat if necessary.

Maintaining Rails, Laser Head, and Work Area

The rails and carriage are essential for smooth, accurate movement. Dust, grease, or debris on these parts can cause jerky motion, leading to poor engraving and even premature wear. Periodically wipe down rails with a dry microfiber cloth, removing particulate matter before it accumulates. For stubborn grime, lightly moisten the cloth with isopropyl alcohol, being careful not to drip liquid onto electrical components.

The laser head, including the nozzle or lens holder, often collects residue from ongoing engraving processes. Clean this area gently, ensuring air pathways are clear and the lens mount is free from debris to avoid misalignment or focus loss. Consistently maintaining the work bed and surrounding area also reduces airborne contaminants, which is a critical aspect of preventative care for engravers and helps avoid unnecessary troubleshooting of laser performance problems down the line.

Frequency and Vigilance: Preventative Care for Engravers

Establish a cleaning frequency based on usage and materials. For high-volume production, daily cleaning may be necessary; hobbyists might find weekly care sufficient. Always err on the side of more frequent attention—underestimating the impact of dust and residue is a common maintenance mistake that shortens machine lifespan and undermines results.

Regular cleaning laser optics and keeping your workspace spotless are among the most effective strategies for laser engraving machine maintenance. These foundational habits ensure every job benefits from maximum power, accuracy, and extended machine lifespan, setting the stage for more in-depth preventative maintenance strategies.

Preventative Maintenance for a Longer Machine Lifespan

In addition to routine cleaning and optics care, scheduled preventative maintenance is the cornerstone of laser engraving machine maintenance for those seeking maximum longevity and performance from their investment. Preventative care for engravers is not just about protecting the delicate optics—it extends to every key system within the machine, ensuring that all moving and mechanical components operate smoothly and consistently over time.

Lubrication and Mechanical Checks: The Foundation of Preventative Care

All moving parts within a laser engraving machine—including rails, linear bearings, and guide rods—require regular lubrication to function properly and to reduce mechanical wear. Over time, dryness or exposure to dust and debris can cause friction, increasing wear on these parts, which not only shortens their lifespan but can also lead to reduced engraving precision. Check the manufacturer’s recommendations for the type of lubricant to use and the suggested frequency of application. Be thorough but cautious: wipe away old excess grease and dirt before adding new lubricant, and avoid contaminating the machine’s optics in the process.

Equally crucial is inspecting belts for proper tension and signs of wear, such as fraying or cracking. Loose or worn belts may slip, causing a loss in accuracy or inconsistent engraving results. Addressing these mechanical necessities as part of preventative care for engravers will substantially aid in extending machine lifespan and avoiding unexpected breakdowns.

Inspecting Air Assist and Cooling Systems: Safety and Performance

The air assist and cooling systems are frequently overlooked, but essential, aspects of laser engraving machine maintenance. Air assist not only keeps the work area clear of smoke and debris but also prolongs the life of the focusing lens by preventing the buildup of particulates on the optics. Regularly check hoses and fittings for leaks, blockages, or damage, ensuring that airflow is steady and unobstructed.

The cooling system—whether water or air-based—protects the laser tube from overheating, a leading cause of premature failure. For water-cooled machines, service the chiller or reservoir regularly by cleaning and refilling it with the proper coolant. Examine hoses for potential leaks and replace coolant at intervals recommended by the supplier. These preventative checks are vital steps towards extending machine lifespan and ensuring safe operation, helping to preempt issues that might otherwise necessitate troubleshooting laser performance due to system failure.

Maintain Software and Firmware for Continued Productivity

Another often understated element of preventative care for engravers is the consistent updating of machine software and firmware. Updated software ensures compatibility with new design files and provides bug fixes that can prevent errors during operation. Scheduled update checks reduce the risk of software-related downtime, support new features, and enhance overall stability. Always back up settings before performing updates to safeguard user configurations.

Organizing Maintenance: Schedules, Logs, and Effective Reminders

The value of laser engraving machine maintenance is maximized through diligent organization. Begin by establishing a regular maintenance schedule based on manufacturer guidance and the machine’s actual usage patterns. For busy workshops, maintain a physical or digital maintenance log that tracks completed tasks, parts replaced, and dates of inspections. This log not only provides a record for warranty claims and future troubleshooting laser performance, but also helps identify recurring issues or trends before they become serious problems.

Use digital calendars or scheduling apps to set recurring reminders for key maintenance tasks such as lubricating parts, checking belts, inspecting the air and cooling systems, or triggering software update checks. By formalizing these preventative actions, you’ll minimize oversight of essential tasks—a common maintenance mistake—and set a routine that reinforces both reliability and productivity, all while focusing on extending machine lifespan through proactive attention.

Avoiding Common Maintenance Mistakes and Troubleshooting Performance Issues

Avoiding Costly Common Maintenance Mistakes

Even the most meticulously constructed laser engravers are vulnerable to damage from easily preventable errors. Among the most widespread common maintenance mistakes is neglecting the regular cleaning of laser optics. Dust, smoke, and residue can quickly accumulate on lenses and mirrors, dramatically reducing engraving precision and overall power. Equally problematic is the use of incorrect cleaning materials—paper towels or household glass cleaners can scratch or chemically damage sensitive optical components. Only specialized wipes and recommended cleaning solutions should be used when cleaning laser optics to ensure surfaces remain pristine and efficient.

Another frequent misstep is forgetting to check filter and airflow pathways. Ignored fans or blocked air assist can lead to overheating, which not only diminishes engraving quality but also shortens component lifespan. Over-lubricating or applying unsuitable lubricants to rails and bearings is another avoidable hazard—stick strictly to the manufacturer’s specifications for all maintenance fluids and agents.

Failing to replace worn consumables such as exhaust filters, belts, or protective lens covers at scheduled intervals can turn a minor maintenance task into a costly system failure. Furthermore, bypassing software prompts for calibrations or firmware updates can result in unpredictable engraving movements and reduced repeatability. The best approach for laser engraving machine maintenance is to always verify with your log or checklist that all scheduled tasks have been performed precisely as recommended.

Troubleshooting Laser Performance Issues

When your laser engraving machine doesn’t operate at peak performance, a systematic approach to troubleshooting laser performance is essential. Early signs of declining machine health include inconsistent cuts, fading engraving lines, abnormal operational sounds, or a noticeable reduction in laser power. The following practical checklist will help you efficiently pinpoint and resolve these issues:

- Inspect and Clean Optics: If engraving quality drops or power seems low, first check the condition of your lenses and mirrors. Residue may be obstructing the laser beam. After powering off the machine, gently clean with approved wipes and solution. Even a small smudge can cause dramatic performance loss.

- Examine Alignment: Misaligned optics or rails can lead to irregular engraving. Use the machine’s test pattern or alignment tools to verify everything is positioned correctly.

- Check Cooling and Airflow: Overheating can throttle performance and cause error codes. Ensure all fans, filters, and water cooling/air assist systems are functioning and free of obstructions.

- Listen for Unusual Noises: New or louder sounds may indicate dried-out bearings, loose belts, or encroaching mechanical failure. Address the source—often a simple lubrication or tightening resolves the issue.

- Review Consumable Parts: Worn or dirty lens covers, belts, or rails should be inspected and replaced if necessary. Skipping this step diminishes machine accuracy and can damage other components.

- Update Software and Firmware: Unexpected errors or erratic engraving paths may be corrected by installing the latest system updates as recommended by your manufacturer.

Maintaining consistency in preventative care for engravers and quickly addressing any abnormal machine behaviors are the keys to extending machine lifespan and sustaining productivity. By avoiding common maintenance mistakes and diagnosing issues promptly with a structured troubleshooting process, you will ensure reliable operation and optimal results from your laser engraving equipment.

Conclusions

Maintaining your laser engraving machine doesn’t just safeguard your investment—it ensures consistent, high-quality results. By following proper cleaning routines, adopting preventative care, and staying vigilant against common maintenance mistakes, you can keep your machine reliable and productive for years to come.

FAQ

Q: Why is routine cleaning important for a laser engraving machine?

A: Neglecting routine cleaning leads to dust, smoke, and residue buildup, diminishing engraver performance, causing power loss, reduced accuracy, and premature component failure. Clean optics ensure focused laser beams and precise designs.

Q: What are the risks of using incorrect cleaning materials on laser optics?

A: Using materials like paper towels or household glass cleaners can scratch or chemically damage sensitive optical components, dramatically reducing engraving precision and overall power. Only specialized wipes and recommended solutions should be used.

Q: How does preventative maintenance contribute to a longer machine lifespan?

A: Preventative maintenance, including lubricating moving parts, inspecting belts, and maintaining air assist and cooling systems, reduces mechanical wear, prevents overheating, ensures proper functioning, and avoids unexpected breakdowns, thereby extending the machine’s lifespan.

Q: What are common signs of declining laser machine performance?

Interested in more Signs? Check out our Signs laser file designs: Click here!

A: Common signs include inconsistent cuts, fading engraving lines, abnormal operational sounds, or a noticeable reduction in laser power. These often indicate issues with optics, alignment, cooling, or worn parts.

Q: Why is software and firmware maintenance crucial for laser engravers?

A: Consistent updating of software and firmware ensures compatibility with new design files, provides bug fixes, prevents operational errors, supports new features, and enhances overall stability, reducing downtime and enhancing productivity.

Subscribe to Our Newsletter

And enjoy FREE Download Files, SALE Alerts and Inspiring TIPS

Bee and Honey Jar Charcuterie Board Engraving | PNG Download #008

Bee and Honey Jar Charcuterie Board Engraving | PNG Download #008

A Beginner’s Guide to Creating 3D Illusion Laser Engravings

A Beginner’s Guide to Crafting the Perfect Laser Cut Box

Creative Laser Cut Box Projects for Every Occasion

Charcuterie Board Engraving File – Wine & Grapes 3D Illusion…

$4.00Original price was: $4.00.$3.00Current price is: $3.00.(25% off)

Bee and Honey Jar Charcuterie Board Engraving File | PNG Download #007…

$4.00Original price was: $4.00.$3.20Current price is: $3.20.(20% off)

Valentine Love Captions: 6 Charcuterie Board Engraving Files…

$8.00Original price was: $8.00.$5.60Current price is: $5.60.(30% off)

American Eagle Flag Laser Engraving File for Charcuterie & Cutting…

$4.00Original price was: $4.00.$2.80Current price is: $2.80.(30% off)