How to Choose the Best Wood Laser Cutter for Your Projects

Choosing the right wood laser cutter is key for high-quality, creative, and efficient woodworking projects. This article explores factors like machine options, design capabilities, suitable woods, and creative uses, providing the essential guidance you need whether you’re a hobbyist or small business owner.

Estimated Reading Time

9-10 minutes

Key Takeaways

- Wood laser cutters (CO2, diode, fiber) offer unparalleled precision for cutting and engraving, providing a significant advantage over traditional wood-cutting methods.

- Achieving high-quality laser-cut results hinges on selecting the appropriate wood type, considering factors like density, resin content, grain, moisture, and adhesive type.

- Prioritize safety when operating laser cutters by ensuring proper ventilation, using fully enclosed machines, and wearing appropriate personal protective equipment.

- Wood laser cutters open doors to diverse creative applications, from intricate art and personalized gifts to professional signage and scalable business branding.

- Success with a wood laser cutter involves optimizing machine settings for different materials, preparing wood correctly, and employing smart marketing strategies for business growth.

Table of Contents

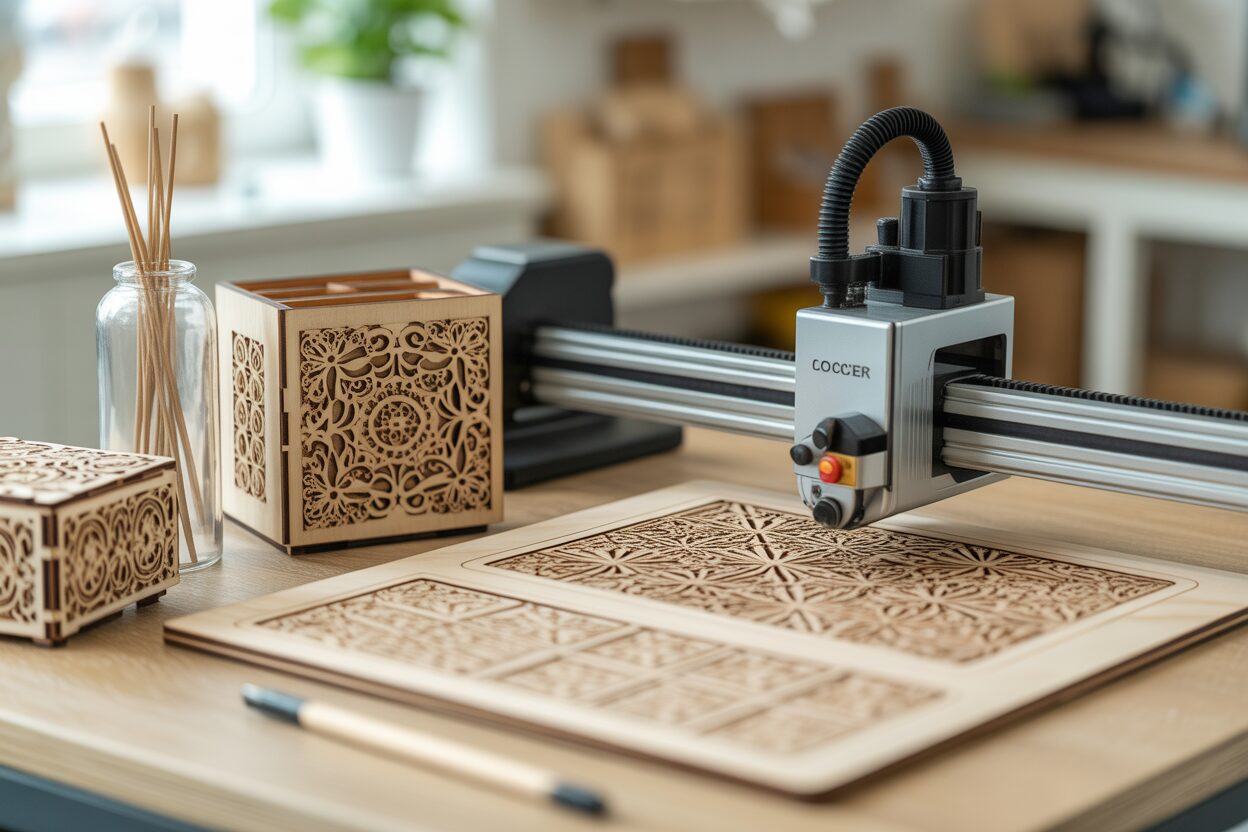

Understanding Wood Laser Cutter Technology and Options

A wood laser cutter is a specialized machine that employs a focused laser beam to slice, engrave, or etch intricate patterns onto various wood materials. Unlike traditional wood cutting machines, which typically rely on physical blades, a wood laser cutting machine for sale utilizes high-intensity light to vaporize or burn through wood with extreme precision. This technique not only delivers clean, detailed cuts but also enables complex wood design cutting machine operations that are difficult or impossible for manual tools or standard saws.

Main Types of Wood Laser Cutters

There are three primary types of wood laser cutting machines: CO2, diode, and fiber. Each has distinct characteristics and is suited for different applications.

- CO2 Laser Cutters: These are the most widely used for wood. CO2 lasers use a tube filled with carbon dioxide gas, producing wavelengths particularly effective for organic materials like wood, leather, and acrylic. They typically range from 30W to 150W, offering both cutting and engraving capabilities. Their versatility and relatively fast speed make them excellent for hobbyists, small businesses, and large-scale production alike.

- Diode Laser Cutters: Diode lasers are smaller, more affordable, and energy-efficient. They use semiconductor technology, resulting in lower power levels (usually below 15W). While commonly found in desktop or entry-level models, they are suitable for thinner or softer woods and primarily for engraving rather than deep cutting. Their portability, lower cost, and ease of use make them popular for personal crafts.

- Fiber Laser Cutters: Although renowned for metalwork, fiber lasers can process certain wood types but are less common in woodworking due to the wavelength not being as well absorbed by organic materials. Their use in wood is limited, but for specialized professional projects involving mixed materials, some shops may use them.

How Laser Cutters Differ from Other Wood Cutting Machines

Traditional wood cutting machines—such as band saws, jigsaws, and rotary tools—remove material using sharp edges and mechanical force. While powerful, these methods often involve significant manual labor, create more waste and debris, and may struggle with very intricate patterns. In contrast, a wood laser cutter focuses energy precisely, enabling sharply detailed designs, crisp edges, and reduced material loss. The result is elevated quality and repeatability that manual tools can’t match, especially vital in professional wood design cutting machine applications.

Features, Benefits, and Cost-Effectiveness

Selecting the right wood laser cutting machine for sale involves evaluating features like laser power, cutting bed size, speed, and supported file formats. Higher wattage models are better for thicker woods and faster cuts, while larger beds accommodate bigger projects or batch processing—crucial for business scalability.

Benefits include automation, precision, minimal clean-up, and the ability to produce both one-off personalized items and bulk quantities with equal skill. For crafters, the ability to translate digital designs directly to wood enables endless creativity. Professional users gain a competitive edge through increased output and consistent results.

Safety Considerations

Safety is paramount. Laser cutters emit powerful beams and generate fumes when cutting wood. Look for machines with fully enclosed cutting areas, proper ventilation systems, and emergency shutoffs. Always operate your wood cutting machine following manufacturer guidelines, using appropriate personal protective equipment, and ensuring your workspace is equipped with adequate exhaust or filtration.

Balancing Cost and Value

CO2 laser cutters represent a sweet spot for many users, balancing price and versatility. Entry-level diode laser machines can be extremely cost-effective for hobbyists and small-scale operations. While industrial fiber lasers are an investment, their high throughput and multi-material capability may justify the cost for certain businesses. Before purchasing a wood laser cutting machine for sale, consider your project frequency and complexity to choose a model that matches your needs and budget.

By weighing these factors and understanding available technology, you can select an ideal wood design cutting machine that maximizes both creativity and productivity.

How to Select the Best Wood for Laser Cutting Projects

Choosing the right wood is fundamental to achieving crisp, clean, and beautifully detailed results with your wood laser cutter. Every type of wood responds differently to laser energy, and understanding these materials will help you create professional-quality crafts, functional pieces, and intricate designs.

Key Factors Affecting Laser-Cut Quality

The ideal wood for laser cutting projects depends on several factors:

- Density and Hardness: Harder, denser woods require more laser power, can burn or char more easily, and may not cut as cleanly as softer woods.

- Resin and Sap Content: Woods rich in resin or oils can produce excess smoke or sticky residue, affecting edge quality and equipment cleanliness.

- Grain and Texture: Fine, uniform grain typically delivers sharper details. Highly figured or unevenly grained wood may cause inconsistent results.

- Moisture Level: Excess moisture can hinder laser performance and lead to warping or rough edges.

- Adhesives (for plywood): Some glues emit toxic fumes or resist laser penetration, so adhesive type is a big consideration.

Softwoods for Laser Cutting

Softwoods like basswood, pine, and cedar are favored for their ease of cutting and engraving. Basswood is especially prized among crafters and model makers because of its smooth texture, minimal grain interference, and light color—all attributes that yield high-contrast engravings and neat edges. Pine is widely available and affordable, but knots and resin pockets can cause uneven burns or messy edges. Cedar’s pleasant aroma and attractive hue make it ideal for decorative items, yet excessive oils may require you to clean your lens more often.

Hardwoods: When Durability Is Needed

Hardwoods such as maple, cherry, walnut, and oak are popular choices for projects demanding strength or a premium look. Maple offers a tight, subtle grain for detailed engraving, making it a top pick for keepsake boxes and signage. Cherry engraves with a rich, dark tone and ages beautifully, ideal for heirloom pieces and custom gifts. Walnut’s deep color gives stunning contrast when engraved. However, oak’s prominent grain can introduce variability to fine designs. Hardwoods generally require a higher-powered laser and slower speeds to prevent scorching, but their resilience is excellent for long-lasting pieces.

Plywood: Versatile for Construction and Crafts

Laser-friendly plywood is engineered specifically for laser cutting. Baltic birch plywood is widely considered the best plywood for laser cutting due to its evenly layered construction with minimal voids and low-resin, interior-grade adhesive. This ensures consistent cuts and clean surfaces for assembly projects like engraved boxes, layered wall art, or intricate ornaments. Avoid exterior plywoods, MDF, or particle board variants, as they may emit harmful fumes or yield rough, inconsistent cuts due to adhesives and dense fillers.

Specialty Woods and Unique Effects

For truly unique pieces, consider specialty woods like bamboo, veneer sheets, or even pre-finished woods. Bamboo brings eco-friendly appeal and a distinctive appearance, but its cross-laminated structure can challenge detailed cuts. Veneers allow you to laser-cut delicate patterns for marquetry or inlay without the risk of charring thicker materials. Experimenting with woods like mahogany, teak, or exotic varieties can add luxurious aesthetics, but always test a sample first, as high oils and varying hardness may affect outcome and machine cleanliness.

Practical Tips for Sourcing and Selection

- Source wood from reputable suppliers who offer laser-grade materials to guarantee consistent results and avoid hazardous adhesives.

- Buy lumber, boards, or plywood that is flat and free of warping, splits, or knots—defects can spoil a finely detailed cut.

- For small crafts, pre-cut blanks sold specifically for laser work can save time and minimize waste.

- Always check your machine’s recommended maximum thickness for each wood type—exceeding it can compromise both result and safety.

- Store unused wood in a dry, temperature-stable area to maintain performance and prevent warping.

Careful wood selection is just as important as machine setup in laser cutting. With the right material, even a mid-range wood design cutting machine will deliver professional results, boosting both creativity and craftsmanship in your work.

Creative Applications and New Possibilities with Wood Laser Cutters

From personal artistry to business innovation, the creative applications for a wood laser cutter extend far beyond simple cuts. Modern wood design cutting machines empower makers to express ideas in new mediums, produce unique products, and serve diverse markets. Leveraging the flexibility of your wood laser cutter, you can explore new frontiers in both craftsmanship and entrepreneurship.

Intricate Art and Decorative Creations

A wood laser cutter excels at producing delicate, detailed works that would be nearly impossible by hand. Artists use these machines to create layered wall art, filigree ornaments, decorative panels, custom jigsaw puzzles, and even elaborate wooden jewelry. By varying machine settings such as power, speed, and focus, makers can achieve different depths and finishes, from subtle engravings to sharp through-cuts. Precise vector files can be translated directly into intricate patterns, giving life to complex designs with incredible repeatability.

For those designing with a wood design cutting machine, try experimenting with stained or pre-finished woods for dramatic visual effects. By combining engraving and cutout techniques, you can make unique marquetry, inlays, or mixed-material collages that become statement pieces in any space.

Custom Signage and Business Branding

Wood laser cutters are a game changer for small businesses seeking professional signage or branded promotional products. Whether crafting company logos on wall plaques, making personalized “open/closed” business signs, or engraving QR codes onto durable wood tags, the machine delivers consistency and speed. Use high-contrast, light-colored woods like maple or birch to ensure deep, legible engravings for business branding applications.

Batch processing, made possible by large cutting beds and software nesting functions, allows you to scale up production while maintaining cost-efficiency. Adding depth to signage via 3D cut layers or combining wood with acrylic backing makes products stand out even further.

Personalized Gifts and Functional Crafts

The ability to personalize is one of the biggest draws of laser technology. Engraving names, dates, or artwork onto everyday objects makes each piece special—think laser engraving on wood pens, custom photo frames, coasters, cutting boards, or keepsake boxes. Small-scale products, like wooden earrings, bookmarks, or desk accessories, are ideal for makers just starting in the market.

For more functional creations, consider making slotted organizers, phone stands, picture holders, or even interlocking toys. The wood laser cutter’s accuracy ensures perfect fits for assemblies, eliminating frustration and wasted material.

Optimizing Machine Settings and Material Preparation

For best results, fine-tune your machine’s settings for each wood type and thickness. Use test cuts to dial in the ideal power and speed—this avoids charring and ensures precise depth for engravings. Clean, sanded, and dust-free surfaces yield sharper engravings and prevent smoke stains. Always keep material flat against the bed for consistent focusing, and use masking tape to reduce surface scorching on lighter woods.

Consider humidity and temperature in your work area, as wood can warp and affect alignment. For intricate cuts, high airflow or an air assist system helps minimize burning, resulting in cleaner edges.

Scaling for Profit and Marketing Tips

Once your craft is perfected, scaling your output is a matter of workflow. Use design software to nest multiple parts in a single cut cycle, maximizing material use and reducing production time. Package product lines in themed sets—such as matching ornament collections or gift bundles—to increase perceived value.

Building a brand around originality and quality is key. Take crisp, well-lit photos of finished products, share process videos online, and tap into social media platforms like Instagram, Etsy, or Pinterest to showcase your offerings. Highlight customization options and quick turnaround times for gift buyers or business clients.

Offer samples to local boutiques or participate in craft fairs to build word-of-mouth. Consider launching workshops or DIY kits for customers eager to learn the craft themselves, extending your reach and adding another profitable dimension to your business.

Harnessing the full creative potential of a wood laser cutter opens endless opportunities—whether for personal artistic satisfaction or as the foundation of a thriving creative enterprise.

Conclusions

Selecting the ideal wood laser cutter can dramatically elevate your woodworking projects and creative business potential. By understanding machine features, design considerations, and the best woods to use, you pave the way for artistic expression and profitable ventures with confidence and skill.

FAQ

Q: What are the main types of wood laser cutters and their uses?

A: There are three primary types: CO2 laser cutters are most common for wood, offering versatility for both cutting and engraving across various materials. Diode laser cutters are smaller, more affordable, ideal for thinner woods and engraving, often found in desktop models. Fiber laser cutters are mainly for metal but can process some wood types, though less commonly used for dedicated woodworking.

Q: What factors should I consider when selecting wood for laser cutting?

A: Key factors include density and hardness (affecting power needs and charring), resin and sap content (can cause smoke/residue), grain and texture (impacts detail sharpness), moisture level (can cause warping), and adhesive type for plywood (some glues emit toxic fumes or resist laser penetration).

Q: How do wood laser cutters improve over traditional wood cutting methods?

A: Laser cutters use a focused laser beam to vaporize or burn through wood, providing extreme precision, sharply detailed designs, crisp edges, and reduced material loss. Unlike traditional methods that rely on physical blades, laser cutting offers superior quality, repeatability, and automation, especially for intricate patterns that are difficult or impossible with manual tools.

Q: What are essential safety considerations for operating a wood laser cutter?

A: Safety is critical. Always look for machines with fully enclosed cutting areas, proper ventilation systems (or adequate exhaust/filtration in your workspace), and emergency shutoffs. It’s crucial to operate the machine according to manufacturer guidelines and use appropriate personal protective equipment (PPE) to protect against powerful beams and fumes.

Q: Can wood laser cutters be used for business and scaling production?

A: Yes, absolutely. Wood laser cutters are excellent for business. They enable the production of custom signage, branded promotional products, personalized gifts, and functional crafts with consistency and speed. Features like large cutting beds and software nesting allow for batch processing and scaling production, maximizing material use and maintaining cost-efficiency, which is crucial for profitability and growth.

Subscribe to Our Newsletter

And enjoy FREE Download Files, SALE Alerts and Inspiring TIPS

A Beginner’s Guide to Creating 3D Illusion Laser Engravings

A Beginner’s Guide to Crafting the Perfect Laser Cut Box

Creative Laser Cut Box Projects for Every Occasion

Charcuterie Board Engraving File – Wine & Grapes 3D Illusion…

$4.00Original price was: $4.00.$3.00Current price is: $3.00.(25% off)

Bee and Honey Jar Charcuterie Board Engraving File | PNG Download #007…

$4.00Original price was: $4.00.$3.20Current price is: $3.20.(20% off)

Valentine Love Captions: 6 Charcuterie Board Engraving Files…

$8.00Original price was: $8.00.$5.60Current price is: $5.60.(30% off)

American Eagle Flag Laser Engraving File for Charcuterie & Cutting…

$4.00Original price was: $4.00.$2.80Current price is: $2.80.(30% off)