Choosing the Right Tools for Laser Engraving Success

Estimated reading time: 7 minutes

Key Takeaways

- Understanding the core components of a laser engraving machine—the laser source, controller, and work surface—is fundamental to achieving precise, repeatable, and high-quality results.

- Strategic selection and integration of accessories like ventilation systems, specialized focusing lenses, rotary attachments, and safety enclosures are crucial for enhancing efficiency, expanding capabilities, and ensuring operator safety.

- Regular maintenance routines, including cleaning optics and checking alignment, are vital for prolonging equipment lifespan and maintaining consistent performance.

- Identifying and resolving common performance issues promptly can prevent costly downtime and ensure continued productivity.

- Timely technological upgrades, such as more powerful laser sources or advanced controllers, are essential for staying competitive and meeting evolving project demands.

Table of Contents

- Understanding the Core Components of a Laser Engraving Machine

- Selecting the Right Accessories and Upgrades for Efficiency

- Maximizing Equipment Performance with Maintenance and Technological Upgrades

- Conclusions

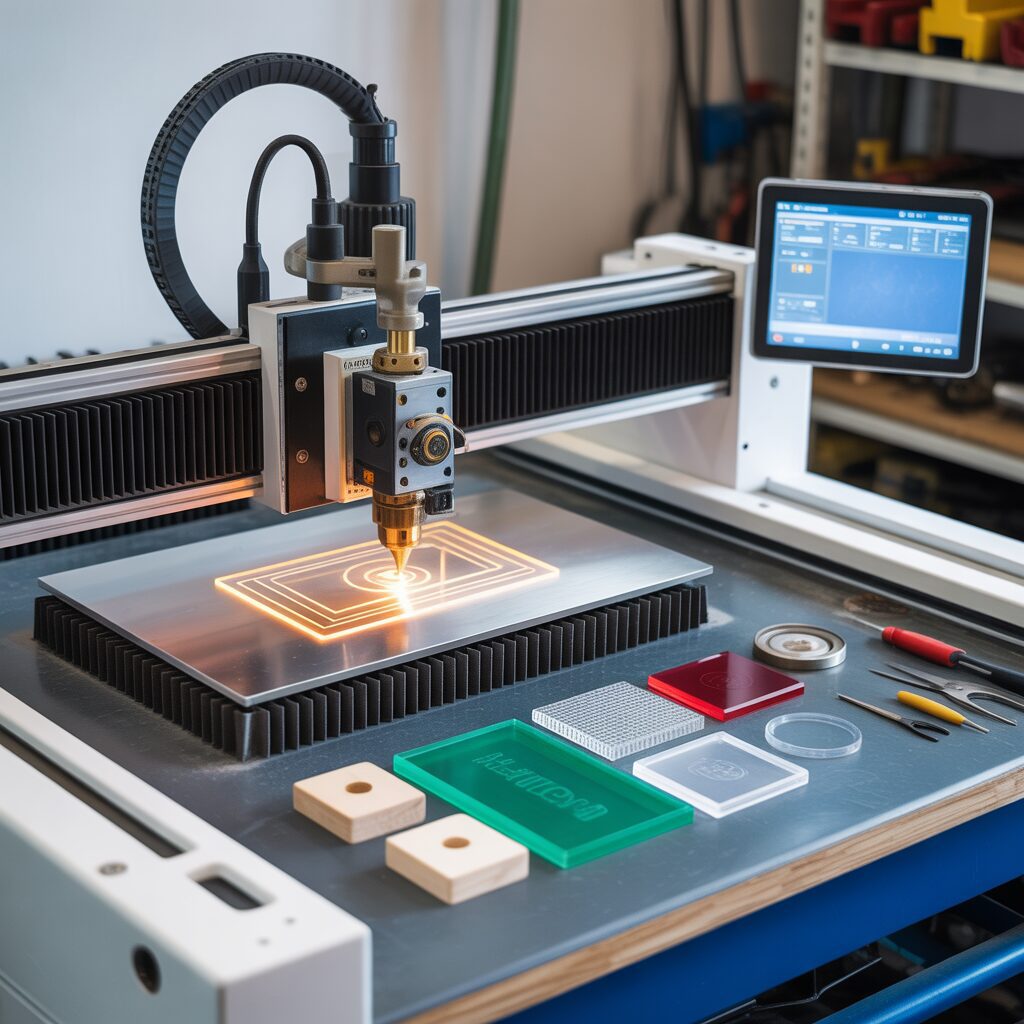

Laser engraving is a rapidly growing field, but your results depend heavily on the tools you use. This article explores the essential components of a laser engraving setup, helps you navigate the variety of machines and accessories available, and offers strategies for caring for and upgrading your equipment. Whether you’re starting out or seeking to maximize your productivity, making smart choices about your tools is crucial.

Understanding the Core Components of a Laser Engraving Machine

A successful laser engraving operation hinges on a deep understanding of the core components that make up the machine itself. Before exploring accessories or enhancements, it’s essential to grasp how the principal elements—the laser source, the controller, and the work surface—combine to deliver precise, repeatable, and high-quality results. Each of these components comes with critical specifications that affect both the quality of engraving and the versatility of the machine with various materials.

The Laser Source: Types and Power Ratings

The heart of every laser engraving machine is the laser source. Common types include CO2, fiber, and diode lasers, each suited for different engraving tasks. The laser source generates the focused energy beam used to interact with the workpiece. Its power rating, typically measured in watts, determines both the depth and speed of engraving.

For softer materials like wood and acrylic, a CO2 laser in the 30 to 100-watt range is often sufficient, allowing for clean cuts and detailed marks. Fiber lasers, on the other hand, excel with metals and plastics, offering higher beam intensities and faster processing speeds. The correct wattage ensures enough power to efficiently process the intended materials without sacrificing detail or risking unwanted burns. Inadequate or excessive power results in either failed engraving or unnecessary damage to your workpiece.

The Controller: Precision and Flexibility

The controller acts as the brain of the laser engraver, translating digital designs into precise movements and pulsing the laser accordingly. Advanced controllers offer a broader range of compatibility with software, better motion algorithms, and support for complex operations such as grayscale engraving and multi-layer processing.

Precision is usually defined in terms of steps per millimeter or minimum feature size. A high-precision controller can reproduce intricate details, even minute text or micro-patterns, which is critical for industries such as electronics marking, jewelry, or fine art. Another vital specification is the repeatability of the controller—its ability to return to the exact same location after multiple passes. This is particularly important for tasks such as multi-pass deep engraving or color infill operations.

Advanced controllers may also allow real-time adjustments, enabling an operator to tweak speed, power, or path without restarting the job. The choice of controller thus heavily influences workflow efficiency, output variety, and the learning curve for new users.

The Work Surface: Size, Material, and Versatility

The work surface—or bed—of the laser engraver determines the maximum size and shape of objects you can process. Common bed materials include anodized aluminum, honeycomb steel, or specialty composites designed for minimizing backscattering and heat buildup.

The size of the bed impacts productivity, allowing either larger single items or multiple smaller objects to be engraved simultaneously. Additionally, the ability to adjust the bed height or use removable sections facilitates the handling of objects of varying thickness—crucial when processing irregular workpieces, cylindrical items, or layered projects.

Another important factor is the mechanism for holding workpieces in place. Magnetic, mechanical, or vacuum hold-downs each have strengths depending on the material and feature tight tolerances for high-precision work.

Critical Factors: Focal Length, Power, and Precision

Each core component intertwines with crucial operational parameters:

- Focal Length: The lens’s focal length dictates the minimum achievable spot size and depth of field. Shorter focal lengths create finer details (ideal for intricate designs), while longer focal lengths are better for cutting thicker materials, albeit with less detail.

- Power: Matching the laser’s power rating to the material is fundamental. Insufficient power leads to incomplete marks, while excessive power can char or melt the workpiece, especially in plastics and thin woods.

- Precision: High-precision systems are essential for detailed, repeatable engravings. This matters most when working with intricate logos, serial numbers, or artwork that leaves no room for misalignment.

Gel these variables with material selection—woods require moderate power and mid-range focal lengths for both raster and vector work, metals demand high-power fiber lasers with pinpoint focus, while most plastics require careful balancing to avoid melting or toxic fumes. Therefore, understanding the attributes of your laser’s source, control unit, and work surface directly informs the range and quality of projects you can undertake, paving the way for meaningful upgrades and strategic accessory choices in more advanced setups.

Selecting the Right Accessories and Upgrades for Efficiency

As laser engraving technology evolves, the role of accessories and upgrades becomes increasingly critical in unlocking your machine’s full capabilities, ensuring safety, and optimizing workflow. While the foundational components set your system’s baseline potential, the right selection of peripherals can greatly enhance both day-to-day efficiency and the scope of projects you can tackle. Key accessories include ventilation solutions, focusing lenses, rotary attachments, and safety enclosures, as well as the latest innovations designed to push performance and productivity even further.

Ventilation Systems: Ensuring Safety and Equipment Longevity

Effective fume extraction and ventilation are indispensable for any laser engraving setup, especially when working with materials that release hazardous gases or particulates during ablation. A well-chosen ventilation system, whether a basic exhaust fan or a sophisticated fume filter, not only protects the operator from inhaling toxins but also shields the laser optics and electronics from build-up and corrosive damage. Advanced systems feature smart sensors that monitor air quality and trigger maintenance alerts, offering peace of mind and reducing the risk of downtime due to unnoticed contamination. Upgrades in this domain now include modular filter cartridges adapted to specific material hazards and quieter, energy-efficient motors for more comfortable, sustainable operation.

Focusing Lenses: Enhancing Precision and Versatility

The selection of focusing lenses directly impacts the quality, speed, and type of engraving you can achieve. Swapping out standard lenses for specialty options—such as shorter focal lengths for ultra-fine details or longer ones for deep-cutting on thick materials—can radically expand your application range. Additionally, some advanced lens mounts incorporate quick-swap mechanisms or autofocus features, reducing the setup time between projects and minimizing alignment errors. High-performance coatings and specialized glass compositions in newer lenses further improve power handling and beam quality, enabling cleaner cuts and more consistent results across diverse substrates.

Rotary Attachments: Unlocking 360-Degree Capability

Engraving cylindrical or uneven objects—like mugs, bottles, or curved signage—requires the integration of a rotary attachment. These devices synchronize object rotation with the laser’s movement, ensuring precise, distortion-free engravings around entire circumferences. Modern rotary attachments offer tool-free adjustments and compatibility with a wider range of object diameters and weights. Some even include dynamic balancing and multi-axis rotation, streamlining complex geometric engravings and multi-process tasks. Investing in a reliable rotary accessory transforms your machine from a single-plane engraver into a true 3D marking powerhouse.

Safety Enclosures: Protection and Workflow Confidence

Safety enclosures are far more than an optional extra—they play a vital role in protecting both operators and the broader environment from laser exposure and particulate emission. Well-designed enclosures often incorporate interlocks that halt laser operation if the enclosure is opened, as well as interior lighting and viewing panels with laser-blocking filters. Recent innovations include modular, expandable enclosures compatible with different machine sizes and automated lockout mechanisms. These advancements not only safeguard users but also streamline compliance with workplace safety regulations, giving you the confidence to focus on creativity and productivity.

Emerging Innovations: Cooling Systems and Optical Upgrades

Technological advancements in supplementary accessories now include more efficient cooling systems—critical for maintaining consistent laser output and preventing thermal drift during extended operations. High-end liquid coolers and closed-loop chillers with digital temperature control reduce fluctuations and extend both laser life and engraving consistency. On the optical front, enhanced element arrays and beam-shaping components enable finer control over spot size and energy distribution, supporting ultra-precise work on sensitive or novel materials.

The interplay of these accessories with core machine components is essential for optimizing your engraver’s safety, adaptability, and overall performance. Thoughtful integration and periodic upgrading of accessories will sustain growth and competitiveness, while also preparing your equipment for future technological advances discussed in the next chapter.

Maximizing Equipment Performance with Maintenance and Technological Upgrades

Routine maintenance is the backbone of consistent, high-quality laser engraving. In the wake of selecting the optimal accessories and staying updated with innovative add-ons, the next critical step is implementing structured care routines and knowing when to invest in technology upgrades to harness the full potential of your equipment.

Establishing Effective Maintenance Habits

Regular maintenance routines are essential not only to prolong the lifespan of your laser engraver but also to maintain its precision and efficiency. Lens and mirror cleaning should top the list of weekly tasks. Dust, smoke residues, and debris from engraving can accumulate on the optics, resulting in diminished laser power, degraded beam quality, and even permanent damage. Always use a recommended lens cleaner and lint-free wipes, delicately wiping the surfaces in a circular motion. Avoid using standard household cleaners or rough cloths that can scratch these sensitive components.

Alignment is another key aspect often overlooked once the machine is operational. Frequent transport, heavy use, or accidental knocks may throw the laser out of alignment. Misalignment manifests as uneven cuts or inconsistent engraving depth. Perform alignment checks monthly or whenever you notice irregularities. Refer to your engraver’s manual for the proper laser path alignment process, and use alignment tools provided by the manufacturer or precision jigs for accuracy.

Ventilation is equally vital. Even with state-of-the-art filtration attachments discussed previously, ducts and exhaust fans can gradually clog with particulates. Clogged systems impair performance and risk overheating sensitive components. Check all air pathways and replace filters or clear out blockages at least every quarter, or more frequently in high-output environments.

Identifying and Resolving Common Performance Issues

As your laser engraver ages or as production volumes increase, you might encounter drops in power, loss of precision, or reliability hiccups. A systematic approach to troubleshooting can prevent costly downtime. If your engraver loses cutting depth or speed, start with optics: dirty or misaligned lenses and mirrors are the most common culprits. Next, inspect your power supply—erratic voltage can hurt output strength. For motion issues, check for worn belt drives, loose stepper motors, or software calibration errors.

If repeat cleaning and tuning fail to restore full performance, the problem may lie deeper, such as a failing laser tube (in CO2 systems) or degraded diodes (in solid-state units). Listen for unfamiliar noises, watch for flickering beams, or inconsistent engraving—these often signal imminent hardware replacement.

Strategic Upgrading for Improved Performance

As technology advances, even well-maintained engravers can benefit from targeted upgrades. If your current projects demand faster turnaround, deeper cuts, or finer detail than your machine can reliably deliver—despite impeccable maintenance—it could be time to invest in a more powerful laser source. Upgrading from a 40W to an 80W CO2 tube, or switching to a higher-frequency fiber laser, substantially expands material capabilities and throughput.

Controller upgrades are another high-impact enhancement. Many legacy engravers can be retrofitted with smart controllers that integrate Wi-Fi connectivity, touchscreen interfaces, and advanced automation. These intelligent systems improve workflow efficiency, enable remote diagnostics, and ensure compatibility with the latest design software.

Other targeted upgrades include swapping standard optics for premium-grade lenses with anti-reflective coatings, which minimize power loss and improve engraving fidelity; or integrating real-time autofocus modules for tasks requiring variable depth engraving.

In deciding when to upgrade, weigh the cost of enhancements against current and anticipated workflow demands. Proactive investment in both maintenance and new technology safeguards your business against obsolescence and keeps your laser engraving operation competitive in a rapidly evolving market.

Conclusions

Choosing the right tools and maintaining them properly are key to achieving optimal results in laser engraving. With a clear understanding of machine types, accessories, and routine care, you can ensure consistent, high-quality output and extend the life of your equipment. Staying updated with technology also keeps your business or hobby competitive in a fast-evolving landscape.

Frequently Asked Questions (FAQ)

Q1: What are the core components of a laser engraving machine?

The core components of a laser engraving machine are the laser source (e.g., CO2, fiber, diode), the controller (which translates digital designs into machine movements), and the work surface (the bed where materials are placed for engraving).

Q2: Why is ventilation important in a laser engraving setup?

Effective ventilation systems are crucial for safety and equipment longevity. They protect the operator from inhaling hazardous fumes and particulates released during engraving, and they prevent corrosive build-up on the laser optics and electronics, which can diminish performance and cause damage.

Q3: How often should I clean the lenses and mirrors of my laser engraver?

Lens and mirror cleaning should ideally be a weekly task. Accumulation of dust, smoke residues, and debris can significantly reduce laser power and degrade beam quality, potentially leading to permanent damage if left unaddressed.

Q4: When should I consider upgrading my laser engraver?

You should consider upgrading your laser engraver if your current projects demand faster turnaround, deeper cuts, or finer detail than your machine can reliably deliver, even with impeccable maintenance. Upgrades like a more powerful laser source or an advanced controller can significantly enhance capabilities and throughput.

Q5: What are rotary attachments used for in laser engraving?

Rotary attachments are used to engrave cylindrical or uneven objects such as mugs, bottles, or curved signage. They synchronize object rotation with the laser’s movement to ensure precise, distortion-free engravings around the entire circumference of the item, transforming a flat-bed engraver into a 3D marking tool.

Subscribe to Our Newsletter

And enjoy FREE Download Files, SALE Alerts and Inspiring TIPS

A Beginner’s Guide to Creating 3D Illusion Laser Engravings

A Beginner’s Guide to Crafting the Perfect Laser Cut Box

Creative Laser Cut Box Projects for Every Occasion

Charcuterie Board Engraving File – Wine & Grapes 3D Illusion…

$4.00Original price was: $4.00.$3.00Current price is: $3.00.(25% off)

Bee and Honey Jar Charcuterie Board Engraving File | PNG Download #007…

$4.00Original price was: $4.00.$3.20Current price is: $3.20.(20% off)

Valentine Love Captions: 6 Charcuterie Board Engraving Files…

$8.00Original price was: $8.00.$5.60Current price is: $5.60.(30% off)

American Eagle Flag Laser Engraving File for Charcuterie & Cutting…

$4.00Original price was: $4.00.$2.80Current price is: $2.80.(30% off)